Pressure Sensitive Labels

What are pressure sensitive labels?

Pressure sensitive labels are the original labeling option, fondly known as the sticker. Making up the most common labeling category, these labels adhere to a surface via pressure. This is the original PSL (sorry Starbucks), and it is also the most variable and flexible labeling choice. Pressure sensitive labels can be printed on an incredibly diverse range of materials, they can implement tons of design features, and are able to be made in virtually any shape or size. With such flexibility, it’s no surprise that this classic labeling technology makes up approximately 80% of the labels you see.

Pressure sensitive labels can be printed using virtually any printing technique. Flexography, or flexographic printing, is a printing technology that uses a rolling press equipped with a flexible relief plate to transfer ink onto a label surface. This printing option allows for a great variety of design possibilities and can be especially cost effective for long-run printing needs.

Flexo Print Pressure Sensitive Labels

Digital printed pressure sensitive labels are produced through laser or inkjet printing, meaning no relief plate is used. This option is flexible, economical, and quick, giving a wide range of design options and the ability to work with many different label materials. Digital PSLs are an especially good choice for shorter print runs, and can be used in any scenario to create beautiful, cost effective designs.

Digital Print Pressure Sensitive Labels

Thermal Print Pressure Sensitive Labels

PSLs are a common application in thermal printing. Thermal printing, as the name suggests, uses heat in its printing process. A thermal print head is applied to a thermal-relief label or to a thermal transfer ribbon to create its images. Thermal PSLs allow for variable data to be printed on pre-existing label substrates including barcodes, serialized numbers, product information, and more.

Shop Pressure Sensitive Labels in the Derksen Co. Store

Pressure Sensitive Label Benefits

No matter your labeling needs, this classic labeling technology has lots to offer.

Flexible Application

PSLs can be used in almost any industry for almost any labeling need. From barcodes on products, to food packaging, to branding and beyond, this labeling option is incredibly diverse in its applications.

Material Diversity

The pressure sensitive labeling technology works with a great variety of materials. The label surface, called the substrate, can range from paper to polys and plastics, to scratch-off materials, to textiles, and more.

Design Features

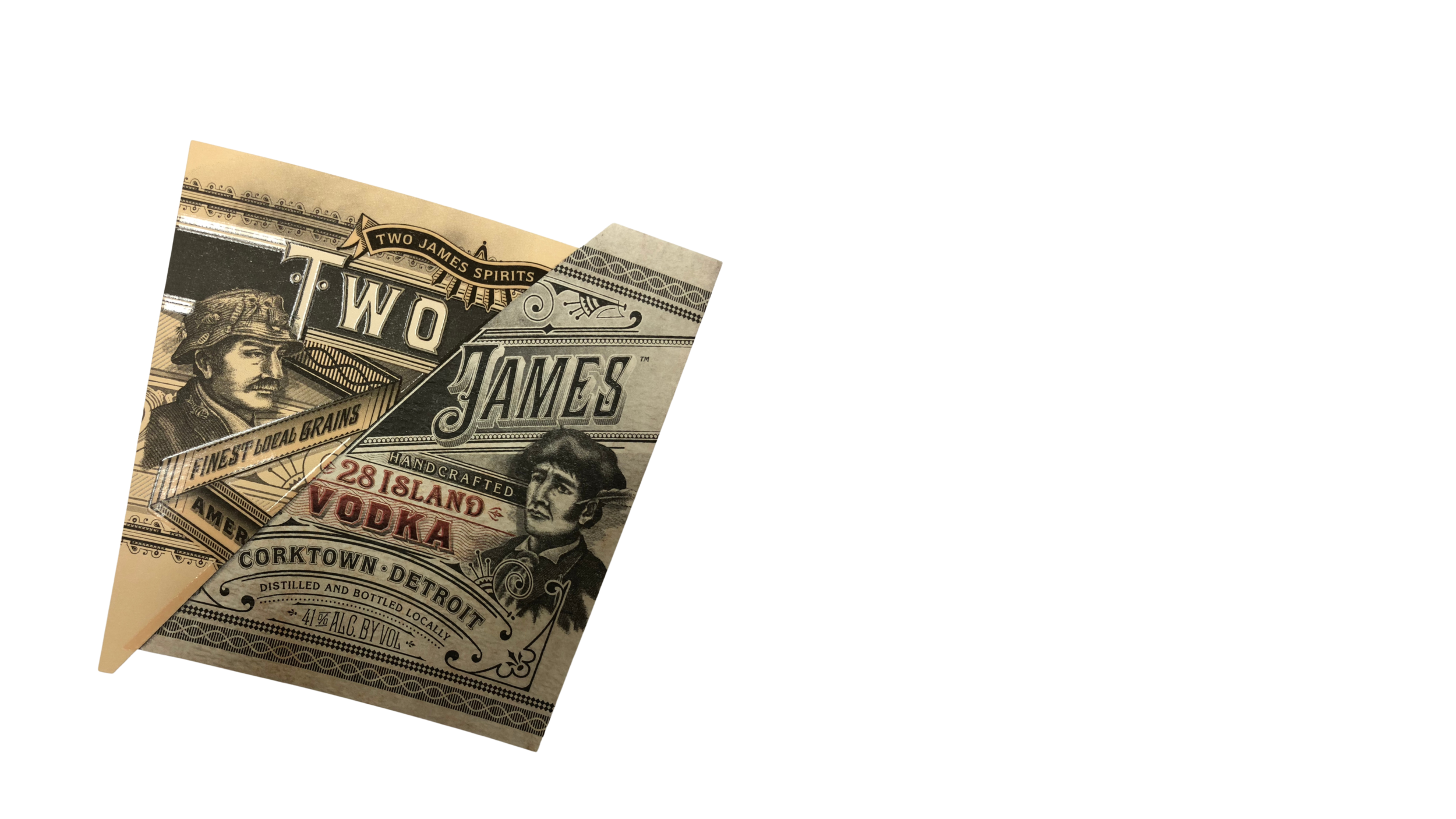

PSLs are notoriously flexible when it comes to design. They can combine features such as specialty inks, foils, varnishes and coatings, embossing and debossing, specialty die-cuts, and much, much more.

Contact Us

Pressure sensitive labels are a great solution for all types of product packaging needs. Contact us at Derksen Co. to find out more about this label technology and to see how you can implement PSL labels into your branding strategy.

How can Pressure Sensitive Labels be Used?

With their variety in design features, ability to be printed with flexo, digital, and thermal printing techniques, and their variability in substrate options, PSLs can be used in almost any industry for almost any use. Some common applications include beer and wine labels, food labels, and product labels. PSLs can also be extremely useful in shipping and logistics industries, in packaging and tracking operations, and in auto identification applications. This classic label technology also has big benefits for branding and marketing purposes, and can suit needs as diverse as large-scale vinyl decals to button-sized compliance labels.

Pressure Sensitive Label Design

-

Substrates

PSLs can accommodate a diverse range of substrates from various papers to metallics, to shiny holographics and clear polys, to textiles like velvet and burlap, the material you choose for your PSL can make all the difference in design.

-

Specialty Inks

Implementing specialty inks into your PSLs can really make an impact. From metallic and fluorescent inks, to changeable inks like thermochromic, photochromic, and phosphorescent (glow in the dark), to interactive inks like scratch-off and scratch-and-sniff, the design possibilities are endless.

-

Foils

Both hot and cold pressed foils can be integrated in your PSL design. Either option will give you shining details with cold foiling acting as an overlay and hot foiling as an embossed detail. No matter which you choose, foils can make your label catch the eye.

-

Embossing & Debossing

Embossing and debossing can be added to your PSL design to create tactile details within your label artwork. Raised or impressed text and design features can make your label an interactive experience.

-

Die Cuts

Die cutting can create complex shapes and cut outs in your PSL artwork. From traditional dies to blade and laser cutters, to freeform cutters, your label artwork need not be confined to the printed surface.

-

Varnishes & Coatings

Varnishes and coatings can really change the way your PSL takes shape. Gloss and matte finishes can make your design look polished and vibrant, while concentrated spot details can enhance artwork and produce raised details.