What are Label Applicators?

LABEL EQUIPMENT AND LABEL APPLICATION

Label applicators are a vital part of the labeling process. Once you’ve got your label designed and printed, you then need to apply the label to the surface of your product. Label applicators help you to streamline your production process and aid you in the affixing of your label so it is well-placed every time. We’re going to detail label equipment and label application. Read on to find out what label applicators are and how they can help you in your product production.

LABEL APPLICATOR BASICS

Let’s start with the basics: label applicators are machines that are used to apply labels to a product surface. There are many different types of label applicators, which we’ll get into below. For now, we’ll just note the basic functions. The label applicator takes a roll of labels, dispenses them, and applies them to the product surface. Generally, there are three categories of applicators: manual, semi-automatic, and automatic. In this post, we’re going to focus on manual and semi-automatic. These are the two categories that Take-A-Label application devices cover, which we’ll be featuring below. Within the three broader categories of applicators, there are a wide range of devices that have particular uses depending upon your product’s shape and size.

TYPES OF LABEL APPLICATION DEVICES

Hand-Held Label Applicator

Hand-held label applicators are easy to use and help to increase the accuracy of label placements. Usually, hand-held applicators are a good choice for smaller labels and for application procedures which require flexibility and mobility.

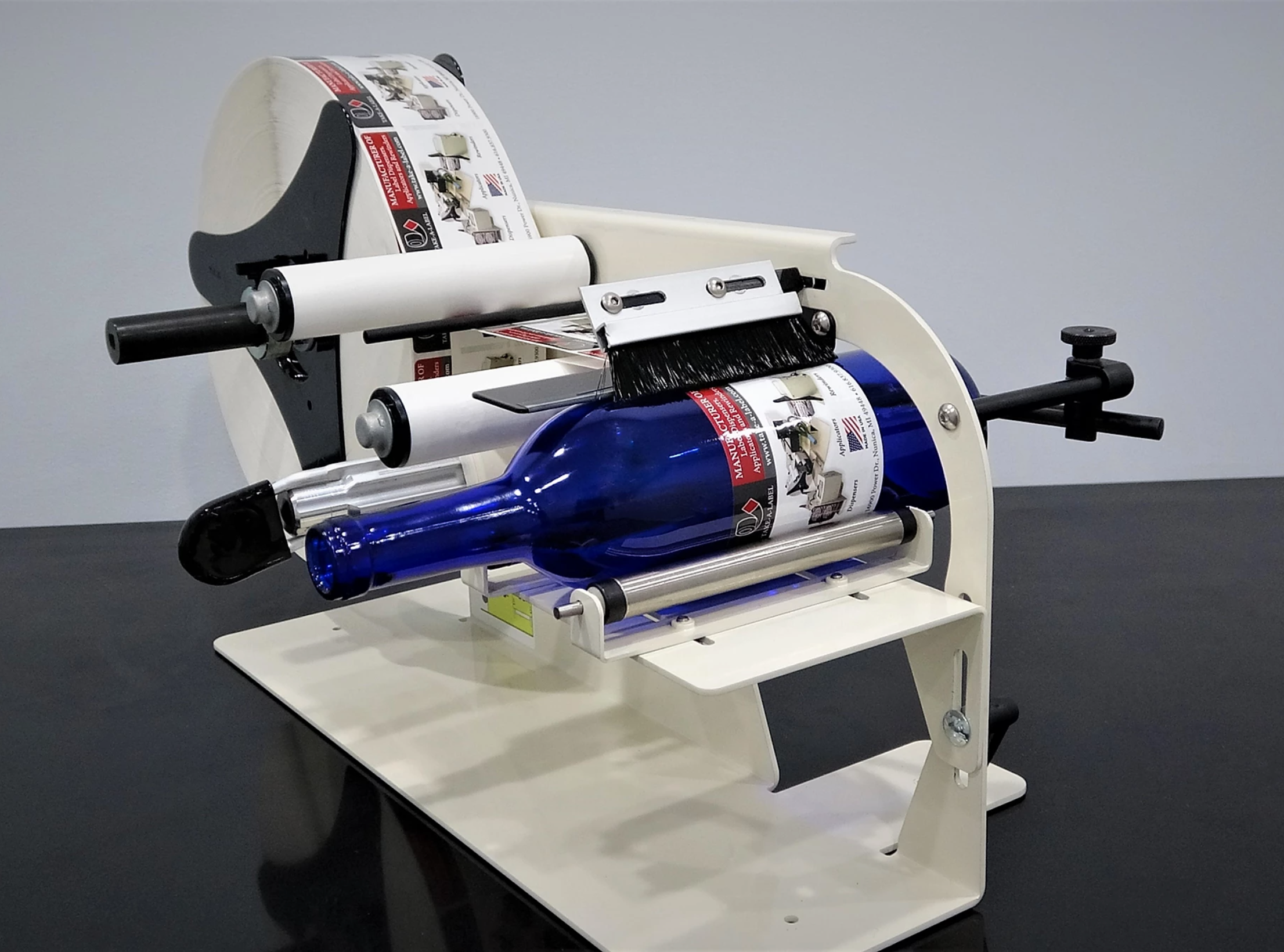

Bottle Label Applicator

Bottle label applicators are specially designed to accommodate cylindrical product containers and apply your labels smoothly to the product surface. Bottle applicators come in both manual and semi-automatic variations and generally use either a roller or brush application.

Tamp Label Applicator

Tamp label applicators use a device called a tamp to place the product label on the container’s surface. The tamp is essentially a small device that pushes the label onto the product by force, creating a seal between label and product.

Wipe-on Label Applicator

Wipe-on label applicators are seen in both round and flat product label applications. The brush sweeps over the label surface to adhere it to the product. These type of applicators can be useful in a variety of application situations and suit a wide range of product container sizes.

TAKE-A-LABEL

Derksen Co. is a proud distributer of Take-A-Label application, dispenser, and rewinder systems. Take-A-Label is an industry leader in label application, dispenser, and rewinder equipment, producing innovative labeling machinery and offering custom solutions for all types of products and production needs.

Keep following the Derksen Co. blog for further information on label equipment and label application. If you want to learn about this topic or about other labeling-related queries, contact us using our inquiries page or by filling out our contact us form. You can also reach the Derksen Co. team by calling 920-685-4000 or emailing team@derksenco.com.